Stepper motors are gaining popularity in robotics and automation. They offer precise control and reliable performance. In robotics and automation, stepper motors are key for accurate and efficient movement.

Stepper motors bring many benefits, like high torque at low speeds and cost-effectiveness. As technology advances, their use in robotics and automation will grow. This will drive innovation and improvement in many industries.

Understanding the Basics of Stepper Motors

Stepper motors are key in precise control systems, like robotics. They are known for their accuracy and reliability. This makes them perfect for many uses. To see why they’re great for robotics, we need to know what they are, their parts, and how they work.

Stepper motors move in steps, giving precise control over their position and speed. They use electromagnetic coils and a permanent magnet rotor. The coils are turned on in a certain order. This creates a magnetic field that moves the rotor, leading to precise movement.

Definition and Core Components

A stepper motor has a stator, rotor, and control system. The stator doesn’t move, while the rotor does. The control system makes sure the motor moves as it should, in the right direction and speed.

Working Principle of Stepper Motors

Stepper motors work by electromagnetic induction. When electric current flows through the coils, a magnetic field is made. This field interacts with the rotor, making it move. By changing when the coils are turned on, the motor moves in a controlled way.

Different Types of Stepper Motors

There are many types of stepper motors, like permanent magnet, variable reluctance, and hybrid. Each type is good for different things. Knowing about these types helps pick the best motor for robotics, where control is key.

Some common motors in robotics include:

- Permanent magnet stepper motors

- Variable reluctance stepper motors

- Hybrid stepper motors

In summary, knowing about stepper motors is vital for robotics. By choosing the right motor and understanding how it works, we can make robots that are efficient and reliable.

| Motor Type | Description |

|---|---|

| Permanent Magnet | Uses a permanent magnet as the rotor |

| Variable Reluctance | Uses a variable reluctance rotor |

| Hybrid | Combines permanent magnet and variable reluctance technologies |

Why Stepper Motors Are Used in Robotics: A Complete Overview

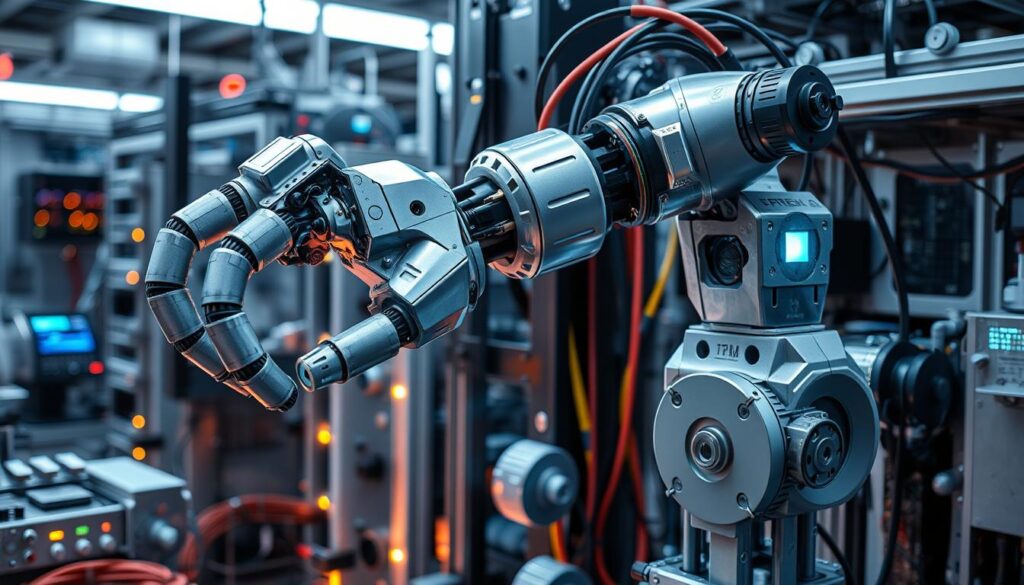

Stepper motors are gaining popularity in robotics for good reasons. They offer high precision and reliability. This makes them perfect for robots that need to move accurately and control their actions well. In robotics, stepper motors power many tasks, like robotic arms, grippers, mobile robots, and self-driving cars.

Stepper motors bring several benefits to robotics:

- High precision and accuracy

- Reliability and durability

- Cost-effectiveness and energy efficiency

- Low maintenance and easy repair

These advantages make stepper motors a top choice for robotics makers and developers. As robotics keeps evolving, the need for stepper motors will likely rise. This will push for new stepper motor technologies.

Stepper motors are also valued for their flexibility and versatility in robotics. They fit into many robotic systems, from simple machines to complex self-driving vehicles. Their precision and reliability make them key to many robotic tasks. Their use is expected to grow even more in the future.

Key Benefits of Stepper Motors in Robotic Applications

Stepper motors bring many advantages to robotics and automation. They are great for tasks that need precise control. Their ability to control position accurately, offer high torque at slow speeds, and be cost-effective makes them perfect for robots.

In robotics and automation, stepper motors stand out. They have special features that make them valuable. Some of these benefits include:

- Precise position control, allowing for accurate movement and positioning of robotic components

- High torque at low speeds, enabling robots to perform tasks that require significant force, such as lifting or moving heavy objects

- Cost-effectiveness and reliability, reducing maintenance and replacement costs, and increasing overall system efficiency

These advantages are key in robotics and automation. They help robots work efficiently and reliably. Stepper motors help achieve high precision and reliability, making them great for many tasks.

Using stepper motors in robotics offers many benefits. These include better precision, more efficiency, and lower costs. As robotics and automation grow, the need for precise control systems and reliable motors will increase. This makes stepper motors a vital part of advanced robotic systems.

| Benefit | Description |

|---|---|

| Precise Position Control | Accurate movement and positioning of robotic components |

| High Torque at Low Speeds | Enabling robots to perform tasks that require significant force |

| Cost-Effectiveness and Reliability | Reducing maintenance and replacement costs, and increasing overall system efficiency |

Common Applications of Stepper Motors in Modern Robotics

Stepper motors are key in the future of robotics. They are used in many fields like manufacturing, healthcare, and service robotics. Their precision and reliability make them perfect for tasks needing exact positioning and control.

In robotics, stepper motors control industrial automation like robotic arms and conveyor belts. They also power service robotics, like vacuum cleaners and healthcare robots. The growth of stepper motor applications is vital for robots to do more complex tasks with better precision.

Some common uses of stepper motors in robotics include:

- Industrial automation and manufacturing

- Service robotics, such as robotic vacuum cleaners and lawn mowers

- Healthcare robotics, such as robotic surgery and patient care

- Autonomous vehicles and drones

Stepper motors bring many benefits to robotics, like high precision, reliability, and cost-effectiveness. As robotics keeps evolving, the need for advanced stepper motor applications will grow. This will push innovation and development in the field.

| Application | Description |

|---|---|

| Industrial Automation | Control of robotic arms, conveyor belts, and other machinery |

| Service Robotics | Robotic vacuum cleaners, lawn mowers, and healthcare robots |

| Autonomous Vehicles | Control of autonomous cars, drones, and other vehicles |

Technical Specifications and Selection Criteria

Choosing the right motor for robotics is all about the technical specs. You need to look at voltage, current, step angle, resolution, and torque. These details help make sure the motor fits your project’s needs.

Technical specs are key for a robot’s performance and efficiency. Here are some important things to think about:

- Voltage and current requirements: The motor’s voltage and current must match the system’s power supply.

- Step angle and resolution: These determine the motor’s precision and accuracy.

- Torque specifications: The motor’s torque must be enough for the load and application needs.

By carefully looking at these specs, developers can pick the best motor for their robot. This ensures the robot works well and efficiently.

| Specification | Description |

|---|---|

| Voltage | The voltage required by the motor, typically measured in volts. |

| Current | The current required by the motor, typically measured in amps. |

| Step Angle | The angle of rotation of the motor per step, typically measured in degrees. |

| Torque | The rotational force of the motor, typically measured in newton-meters. |

By focusing on these technical specs and choosing the right motor, developers can build efficient robots. These robots will meet their specific needs and requirements.

Integration Challenges and Solutions

When working on robotics integration, stepper motor challenges can pop up. These include compatibility issues, software problems, and hardware needs. It’s key to know what the robotic system and stepper motor need.

Some common issues with stepper motor integration are:

- Compatibility problems with the robotic system’s control board

- Software issues with the system’s programming language

- Hardware needs, like motor size and torque

To solve these problems, developers can try different solutions. For example:

Using a control board that matches the stepper motor’s specs, or a software library that makes integration easier.

By tackling stepper motor challenges with the right solutions, developers can integrate stepper motors well. This leads to precise control and efficient operation in robotic systems.

Comparing Stepper Motors with Other Motor Types

Choosing the right motor for robotics is a big decision. Engineers must weigh the stepper motor advantages against other options. A detailed motor comparison is key to picking the perfect motor for the project.

Servo motors and DC motors are common alternatives to stepper motors. Each has unique benefits and drawbacks. It’s important to understand the differences to make the best choice.

Key Considerations for Motor Selection

- Precision and accuracy requirements

- Torque and speed specifications

- Power consumption and efficiency

- Cost and reliability factors

A motor comparison table can highlight the main differences. Here’s a summary of stepper, servo, and DC motors’ characteristics:

| Motor Type | Precision | Torque | Speed | Power Consumption |

|---|---|---|---|---|

| Stepper Motor | High | High at low speeds | Variable | Low to medium |

| Servo Motor | Very high | High | High | Medium to high |

| DC Motor | Medium | Medium | High | Low to medium |

By looking at these factors, engineers can decide which motor is best. This choice depends on the stepper motor advantages and the project’s needs.

Advanced Control Techniques and Programming

To get the most out of stepper motors in robotics, you need advanced control and programming. Precise control systems help robots do complex tasks with great accuracy. This is key for tasks that need careful movements.

Programming is vital for this precision. It lets developers tweak the motor’s performance and adapt to new situations.

Some important parts of advanced control include:

- Speed control: Changing the motor’s speed for better performance and efficiency.

- Position control: Controlling the motor’s position for accurate movements.

- Torque control: Managing the motor’s torque for different loads and situations.

With robotics programming and precise control, developers can make advanced robots. These robots can do many tasks with great accuracy and efficiency.

Future Trends in Stepper Motor Technology

The future of robotics is linked to stepper motor tech. As we need more precise control and efficient motion, experts are working hard. They aim to make stepper motors more efficient and compact for complex robots.

In the robotics future, stepper motors will be key for advanced and self-driving robots. Emerging technologies like AI and machine learning need these motors to work well. The main trends in stepper motor tech include:

- Using new materials and methods to boost motor efficiency and reliability

- Creating smaller, integrated stepper motors for robots

- Focusing on saving energy and cutting down power use

As robotics grows, stepper motors will stay vital in many systems. By investing in research, makers can keep stepper motors leading in robotics.

Industry innovations, like advanced control techniques and programming, will shape stepper motor tech’s future. These advancements will help make stepper motors more advanced and efficient for robotics.

Conclusion: The Future of Stepper Motors in Robotics

Stepper motors are key in robotics, giving robots precise control and high torque. They are also cost-effective. These motors have changed how robots work, allowing them to do complex tasks with great accuracy. The future of stepper motors in robotics and automation looks very promising.

New technologies will make stepper motors even better. Improved driver circuits and control algorithms will boost their performance. Leaders in the field are also working on new materials and designs. This will keep stepper motors at the forefront of robotics.

Robotic tasks are getting more complex, and so is the need for precise motion control. Stepper motors are perfectly suited for this, making them essential in robotics. The future of robotics is closely tied to stepper motor technology. This will lead to even more impressive achievements in precision and innovation.