Choosing the right servo motor is key for a robotic arm’s performance. It can be tough, but with the right help, you can make a good choice. We’ll show you how to pick the best servo motor for your robotic arm. This includes understanding how servo motors work and figuring out torque needs.

Servo motor selection is critical in robotics. The right motor can make your robotic arm more precise, faster, and productive. Whether you love robotics or are an engineer, knowing about servo motors is vital. It helps in building a system that works well.

Thinking about servo motor selection and robotic arm design is important. It helps you create a system that fits your needs. In the next parts, we’ll explore servo motors more. We’ll give you the knowledge to choose the right servo motor for your robotic arm.

Understanding Servo Motors and Their Role in Robotics

Servo motors are key in robotics, known for their precision and reliability. To pick the right servo motor for your robotic arm, knowing the basics is vital. They can rotate and stay in place, perfect for many robotic tasks.

In robotics, servo motors control the movement of arms, legs, and more. They’re used in many fields like manufacturing, healthcare, and aerospace. Their ability to rotate and hold position makes them great for precise tasks.

What is a Servo Motor?

A servo motor uses feedback to control its position, speed, and torque. They’re made for precise control, often used in robotics. Feedback tools like encoders and potentiometers help control the motor’s movement.

How Servo Motors Function in Robotic Applications

Servo motors control robotic parts’ movement in applications. They offer precise control, used in tasks like assembly and welding. Their ability to rotate and stay in place is perfect for accurate tasks.

Types of Servo Motors Available

There are DC, AC, and brushless servo motors, each with unique features. Knowing these differences is key to choosing the right servo motor for your robotic arm.

Essential Specifications to Consider When Selecting a Servo Motor

Choosing the right servo motor for your robotic arm is key. You need to look at the motor’s torque, speed, and power. Also, make sure it fits with your robotic arm’s control system. Knowing these servo motor selection criteria helps your robot work better and more efficiently.

Here are some important factors to think about:

- Torque: The rotational force the motor can apply.

- Speed: The motor’s top rotational speed.

- Power: The energy the motor can output.

- Compatibility: How well the motor works with your robotic arm’s control system.

By looking at these motor specifications and servo motor selection criteria, you can pick the best servo motor. This ensures your robotic arm moves precisely and performs at its best.

Calculating Torque Requirements for Your Robotic Arm

When designing a robotic arm, torque calculation is key to picking the right servo motor. The robotic arm design must think about the loads and movements. To figure out the torque needs, you must grasp the basics of torque and its role in your arm.

The load the motor must handle is a major factor in torque calculation. This includes the arm’s weight and any external loads. Don’t forget to add safety factors like friction and inertia for reliable operation.

Understanding Torque Basics

Torque measures the rotational force that makes an object turn. In robotic arm design, it’s vital for lifting and moving loads. The needed torque varies based on the application and loads.

Load Calculations and Safety Factors

To find the torque needs, consider these factors:

- Load weight and size

- Friction and inertia

- Safety factors, like a 10-20% margin of error

Dynamic vs Static Torque Considerations

Don’t just look at static torque. Dynamic torque, like movement and acceleration, is also important. This ensures your servo motor meets your robotic arm design‘s demands.

| Factor | Description |

|---|---|

| Load Weight | The weight of the load being lifted or moved |

| Friction | The force opposing motion between two surfaces |

| Inertia | The resistance to changes in motion |

How to Select Servo Motor for Robotic Arm: Step-by-Step Guide

Now that you know what your robotic arm needs, it’s time to pick the right servo motor. You’ll look at several things, like your budget and the guide for choosing servo motors.

First, figure out what your robotic arm will do and how much it will carry. This helps you find a servo motor that fits your needs.

Determining Application Requirements

Think about these things when figuring out what you need:

- Load capacity: How much weight will your robotic arm lift or move?

- Speed and accuracy: How fast and precise does your robotic arm need to be?

- Power supply: What power and voltage do you have available?

After you know what you need, match it with what servo motors offer. Look at your budget, performance, and compatibility. This way, you can find the best servo motor for your robotic arm.

Power Supply and Voltage Requirements

Choosing the right servo motor for your robotic arm means looking at power supply and voltage needs. The power supply must give the servo motor the right voltage and current. Voltage requirements change based on the servo motor type and use.

A good power supply keeps the voltage steady and can handle the servo motor’s power use. Here are important things to think about when picking a power supply:

- Input voltage range

- Output voltage regulation

- Current rating

- Efficiency

Knowing your servo motor’s power and voltage needs is key for it to work well. The right power supply prevents damage and ensures the servo motor works its best.

In short, picking the correct power supply and understanding voltage needs are vital for your robotic arm’s success. By looking at these factors, you can find the best power supply and voltage for your servo motor. This will improve its performance and efficiency.

| Power Supply Characteristics | Description |

|---|---|

| Input Voltage Range | The range of input voltages that the power supply can accept |

| Output Voltage Regulation | The ability of the power supply to maintain a stable output voltage |

| Current Rating | The maximum current that the power supply can provide |

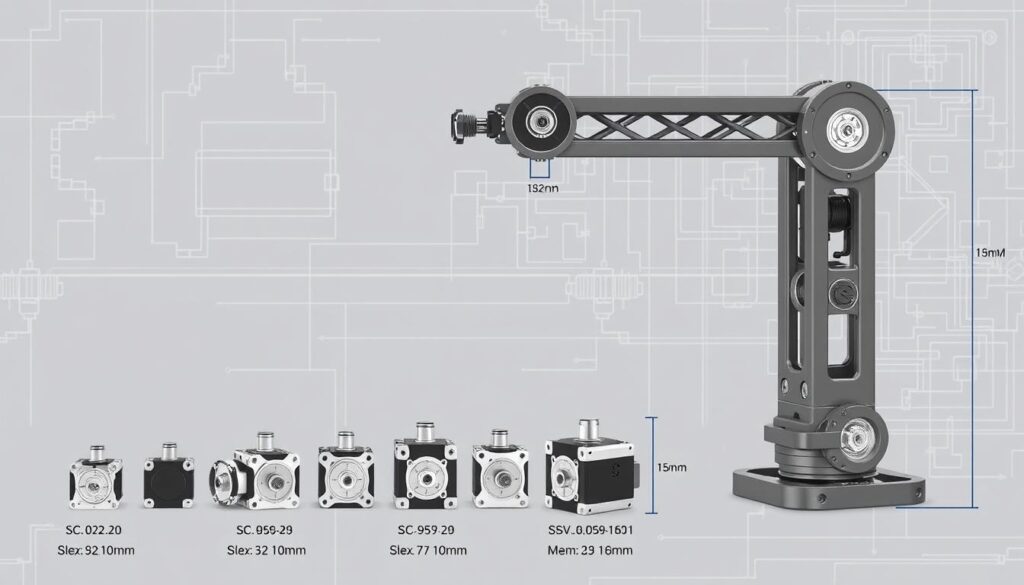

Size and Mounting Considerations

Choosing the right servo motor for your robotic arm is key. You need to think about the size and how it mounts. The motor’s size affects the arm’s design and how well it works.

The size of the servo motor matters for space in your robotic arm. Mounting considerations are also important. They help keep the arm stable and balanced. A good mount keeps the motor in place and handles the stress of use.

When picking a servo motor, consider these things:

- Physical dimensions: The length, width, and height of the servo motor

- Space constraints: The available space within the robotic arm for the servo motor

- Mounting options: The type of mounting system used, such as brackets or clips

- Weight distribution: The distribution of weight within the robotic arm and the impact on the servo motor

A well-chosen servo motor size and mount ensure your robotic arm works great. By looking at these factors, you can find the perfect motor for your needs.

| Factor | Description |

|---|---|

| Servo Motor Size | The physical dimensions of the servo motor |

| Mounting Considerations | The type of mounting system used and its impact on weight distribution |

Control Systems and Communication Protocols

When picking a servo motor for your robotic arm, think about the control systems and communication protocols. This ensures your robotic arm works well with its control board. The control system and communication protocols are key to your robotic arm’s performance.

Digital and analog control systems have different uses. Digital systems are better for tasks needing high accuracy and quick responses. Analog systems are simpler and less costly, ideal for tasks not needing high precision.

Digital vs Analog Control

Digital control systems use PWM to control the servo motor, giving precise control over its position and speed. Analog systems use a continuous signal for control. Choose a control system that matches your servo motor’s communication protocols.

Compatible Control Boards

Make sure the control board you pick works with your servo motor’s communication protocols like UART, SPI, or I2C. This lets the control board and servo motor talk smoothly, controlling the motor’s movements and getting feedback on its status.

By looking at the control systems and communication protocols of your servo motor, you can make sure your robotic arm works well.

Common Pitfalls to Avoid in Servo Selection

Choosing the right servo motor for your robotic arm is key. It’s important to avoid servo motor selection pitfalls to avoid expensive errors. One big mistake is not checking the torque and compatibility needs.

Here are some common mistakes to steer clear of:

- Choosing a motor with too little torque can cause poor performance and damage.

- Using a motor that doesn’t fit with your control system can lead to errors and less functionality.

- Incorrectly mounting or sizing the motor can cause mechanical stress and shorten its life.

To sidestep these servo motor selection pitfalls, carefully match your application needs with the motor’s specs. This ensures your robotic arm works smoothly and efficiently.

Knowing these common pitfalls and choosing the right servo motor can save you from costly mistakes. It also guarantees the best performance of your robotic arm.

Conclusion: Making Your Final Servo Motor Choice

After looking into the important things to consider for your servo motor, it’s time to decide. Choosing the right servo motor is key for your robotic arm’s best performance. Think about torque, size, and control systems to find the perfect match for your project.

This article has given you the tools to pick the best servo motor for your robotic arm. Whether you’re a hobbyist, researcher, or engineer, you now have the knowledge. Follow the steps and avoid common mistakes to build a top-notch robotic system.

With the correct servo motor, your robotic arm will be powerful, precise, and responsive. Take your time to review the important factors and seek advice if needed. Make a well-informed choice to ensure your project’s success in the long run.