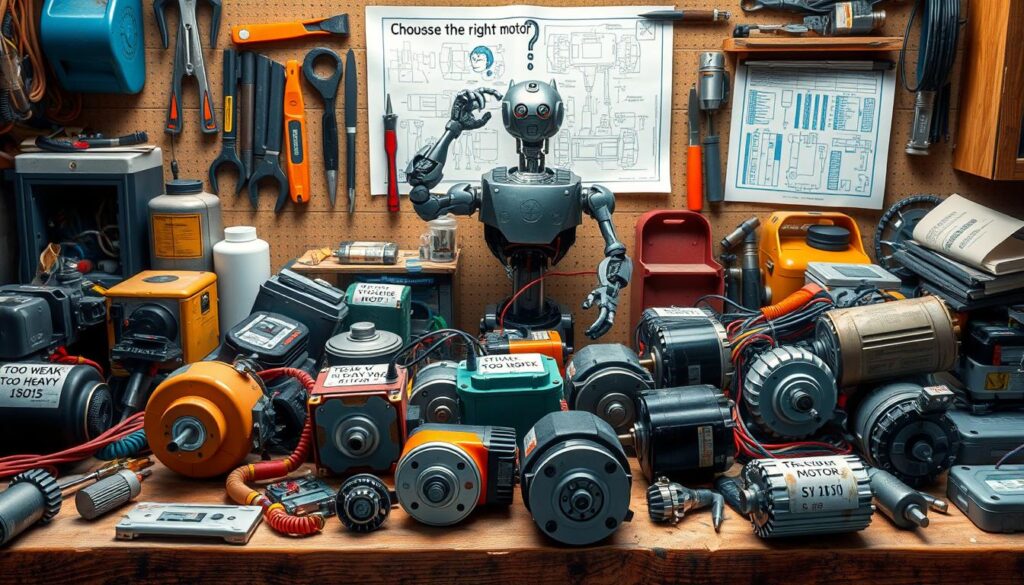

Choosing the right motor for your robot can be tough. There are many motor types out there. We’ll help you pick the best one for your robot, covering motor types, power needs, and more.

Whether you’re new to robotics or have experience, knowing about motor types is key. Think about power, speed, and torque to make the right choice. This will help your robot work better and more efficiently.

Understanding the Basics of Robot Motors

Choosing the right motor is key when building a robot. There are many types, like AC, DC, stepper, and servo motors. Each has its own strengths and uses in robotics. AC and DC motors are often picked for their reliability and efficiency. Stepper and servo motors, though, are great for tasks needing precision.

The motor you choose depends on your project’s needs. Different motor types have their own pluses and minuses. For example, AC motors are good for high-power tasks. DC motors are simpler and cheaper. Stepper and servo motors are perfect for precise movements, like in robotic arms or CNC machines.

- Power requirements: AC motors and DC motors have different power output capabilities.

- Speed and torque: Stepper motors and servo motors offer high precision and control.

- Application: Choose a motor that suits your project’s specific needs, such as robotic arms or CNC machines.

Knowing about robot motors and their uses helps you pick the best one for your project. Whether it’s a simple robot or a complex system, the right motor is vital. It ensures your robot works well and efficiently.

Key Factors That Influence Motor Selection

Choosing the right motor for a robot involves several key factors. These factors are vital for the robot’s performance and efficiency. The robot design is a major factor, as it determines the power, speed, and torque needed.

Here are some important factors to think about when picking a motor for your robot:

- Power requirements: The power needed for the robot’s movements and functions.

- Speed and torque: The speed and torque needed for the robot’s tasks.

- Budget constraints: The budget for the motor and its components.

Understanding these key factors is key to making a good choice for motor selection. By considering these factors and their impact on the robot design, you can find the right motor. This ensures your robot works well and meets its needs.

Power Requirements and Voltage Considerations

Choosing the right motor for your robot is key. You must think about the power and voltage it needs. This means figuring out how much power your robot will use and what voltage it needs. The robot’s weight, speed, and where it will be used all play a part in this.

Power requirements are vital for your robot to work well. You need to figure out how much power it will need based on its use and where it will be. For example, a robot for outdoor use might need more power than one for indoors.

Calculating Power Needs

To figure out power needs, look at a few things:

- Robot weight and size

- Desired speed and acceleration

- Terrain and obstacles

These will help you find out how much power and voltage your robot’s motor needs.

Battery Compatibility

Battery compatibility is also very important. Make sure the motor you pick works with your robot’s battery type and voltage. This keeps the motor and battery safe and makes sure your robot works well.

Voltage Ratings and Limitations

Lastly, think about the voltage considerations and limits of your motor. Make sure the motor’s voltage rating fits your robot’s power supply and battery voltage. This prevents damage and keeps your robot safe.

| Motor Type | Power Requirements | Voltage Considerations | Battery Compatibility |

|---|---|---|---|

| DC Motor | Low to medium | 6-12V | Compatible with most batteries |

| AC Motor | Medium to high | 12-24V | Requires specific battery type |

How to Choose Motor for Robot Based on Project Type

Choosing the right motor selection is key for any robot application. The type of project you’re working on matters a lot. For example, a motor with high torque is best for heavy lifting. On the other hand, a motor with high speed is better for fast movements.

Here are some key factors to think about when picking a motor for your project type:

- Power needs: The power your project needs will help pick the right motor.

- Speed and torque: Your project’s speed and torque needs are also important.

- Size and weight: The size and weight of your project also matter in choosing a motor.

By considering these points, you can make a smart choice for your motor selection. Always pick a motor that fits your robot application well. This will help your project succeed.

Speed and Torque Requirements

Choosing the right motor for your robot is key. You need to understand the speed and torque it needs. Speed and torque work together, affecting how well the motor performs. To figure out the needed torque, think about your robot’s weight, friction, and where it will move.

The relationship between speed and torque is complex. But basically, as speed goes up, torque goes down. This is important when picking a motor. You want one that can handle the needed torque at the right speed. Calculating torque is a big part of this, taking into account your robot’s weight, friction, and speed.

To find the best speed for your motor, think about your robot’s needs. Consider the terrain, weight, and desired speed. Knowing the speed-torque relationship and calculating torque helps you pick the right motor for your robot.

| Motor Speed | Motor Torque |

|---|---|

| 1000 rpm | 10 Nm |

| 500 rpm | 20 Nm |

| 2000 rpm | 5 Nm |

By looking at your robot’s speed and torque needs, you can find a motor that’s just right. This ensures your robot works well and efficiently.

Size and Weight Constraints

When picking a motor for your robot, size and weight matter a lot. The motor size and weight considerations play big roles in your robot’s design and how well it works. A motor that’s too big or heavy can make your robot hard to move and might even get damaged.

To find the right motor, think about these things:

- Available space: Make sure the motor fits in your robot’s design.

- Weight distribution: Keep the weight considerations balanced to avoid instability.

- Power requirements: Choose a motor with enough power but also keep size and weight in mind.

By looking at these factors and thinking about motor size and weight considerations, you can pick a motor that makes your robot work better and look good.

| Motor Type | Size | Weight |

|---|---|---|

| DC Motor | Variable | 0.5-5 kg |

| Stepper Motor | Small to medium | 0.1-2 kg |

| Servo Motor | Compact | 0.05-1 kg |

Motor Control and Programming Considerations

Robot development focuses on motor control and programming. Motor control manages the motor’s performance for efficiency. Programming uses software and algorithms to control the motor. Both are key for the motor and robot to work well together.

Choosing the right driver is important for motor control. Driver requirements like voltage, current, and communication protocols matter. This ensures the motor fits well with the robot’s system.

Control Methods and Programming Interface Options

There are many control methods and programming interfaces. Pulse-width modulation (PWM) and proportional-integral-derivative (PID) control are common. APIs and SDKs help developers write custom programs for motor control.

Developers can make robots more efficient by focusing on motor control and programming. Programming considerations include algorithms and software for motor control. The right motor control system and programming interface are key for a robot’s performance.

- Understand driver requirements and control methods

- Select the most suitable motor for the robot’s system

- Develop custom programs and algorithms for motor control

By following these steps, developers can make robots more efficient and reliable. This ensures the robot performs well and reliably.

Budget and Cost Analysis

When picking a motor for your robot, your budget is key. It’s important to do a cost analysis to stay within your budget. Look at different prices to find the best deal, considering performance, durability, and upkeep costs.

Think about the motor’s long-term value. A cheaper motor might seem good at first, but it might not save you money in the long run. Look at replacement parts, energy use, and future repairs. This way, you can choose a motor that fits your budget and project needs.

Factors Affecting Motor Cost

- Performance requirements: High-torque or high-speed motors tend to be more expensive

- Materials and construction: Durable materials and robust construction can increase the cost

- Brand and reputation: Well-known brands may charge more for their products

- Warranty and support: Comprehensives warranties and dedicated support can add to the cost

By looking at these factors and your budget, you can find a motor that fits your needs without overspending. Make sure to balance your project’s needs with your budget for the best results.

Price Range Comparisons

| Motor Type | Price Range | Performance |

|---|---|---|

| Basic DC Motor | $10-$50 | Low-to-medium torque |

| High-Torque DC Motor | $50-$200 | Medium-to-high torque |

| Stepper Motor | $20-$100 | Precise control and positioning |

By doing a detailed cost analysis and comparing prices, you can choose a motor that fits your budget and meets your project’s needs.

Common Motor Selection Mistakes to Avoid

Choosing the right motor for a robot or any other project is key. Motor selection mistakes can cause problems like poor performance, a short lifespan, or even failure. These errors can be expensive and hard to fix. It’s important to know the common errors people make when picking a motor.

Some common mistakes include not checking the power needs, ignoring voltage, and missing the speed and torque needs. To avoid these, follow best practices. This means calculating power, checking battery compatibility, and picking the right speed and torque.

Here are some tips to help you avoid motor selection mistakes:

- Calculate the power requirements carefully

- Consider the voltage and current requirements

- Select the optimal speed and torque for the application

- Choose a motor that is compatible with the battery and control system

By following these tips and avoiding common mistakes, you can make sure your motor choice is right. This way, you’ll get the best performance, reliability, and a long life for your project.

Conclusion: Making Your Final Motor Selection

We’ve come to the end of our guide on picking the perfect motor for your robot. Now, it’s time to use all you’ve learned. Think about power, speed, size, and your budget when choosing a motor.

By looking at these factors, you can pick the best motor for your robot. Remember, every robot is different. So, take your time to find the right motor for your project.

As you work on your robot, keep using the knowledge from this guide. Stay curious and try new things. Robotics is always changing, and the right motor can help you achieve amazing things.