Robotic arm motors are key to robotic systems, allowing for precise movement and control. There are many types of motors used in robotic arms. Knowing the different types is important for choosing the right one for your needs.

There are various motor types for robotic arms, each with its own benefits. By learning about these types, you can better understand robotic arm motors. This knowledge helps in making the right choice for your specific needs.

Understanding the Basics of Robotic Arm Motors

Robotic arm motors are key to robotic systems, allowing for precise movement and control. To grasp the basics, we need to look at their definition, purpose, and main parts. Servo motors, stepper motors, and DC motors are often used in robotic arms. Each has its own features and uses.

The main job of robotic arm motors is to give the power and control needed for the arm to do tasks. These motors work with other parts like gearboxes and control systems for precise movement. When picking motors, it’s important to think about power needs, speed, and torque.

Definition and Purpose of Robotic Arm Motors

Robotic arm motors are made to give the power and control for the arm to do tasks. They’re used in jobs like assembly, welding, and handling materials. Their goal is to let the robotic arm move with precision and do complex tasks well.

Key Components of Motor Systems

A motor system has the motor, a gearbox, bearings, and a control system. The motor gives the power, and the gearbox and bearings help with smooth movement. The control system manages the motor’s speed and torque for precise control.

Power Requirements and Specifications

Choosing motors for a robotic arm means looking at power needs and specs. Stepper motors and servo motors are often picked for their precision and control. DC motors are used too, for their speed and torque. Here’s a table showing what each motor offers:

| Motor Type | Power Requirements | Speed | Torque |

|---|---|---|---|

| Servo Motors | Low to medium | High | Medium to high |

| Stepper Motors | Low to medium | Medium | Low to medium |

| DC Motors | Medium to high | High | High |

Knowing the basics of robotic arm motors helps designers and engineers pick the right ones. This ensures the arm moves precisely and is controlled well.

The Evolution of Motors in Robotics

Robotic development has seen big changes over time, with motor tech advancements being key. The arrival of linear actuators marked a big step, allowing robots to work more precisely and efficiently. Choosing the right motor is critical, considering power, speed, and torque for the best results.

Choosing the right motors is vital for robots to work well. Linear actuators are now common in robotics because they offer precise movement. It’s important to pick a motor that fits the robot’s needs.

- Power requirements: The motor must be able to provide sufficient power to perform the required tasks.

- Speed and torque: The motor must be able to operate at the required speed and torque to ensure efficient performance.

- Precision and control: The motor must be able to provide precise movement and positioning to ensure accurate performance.

Understanding motor evolution in robotics helps make robots better. Linear actuators have been a big help. Their ongoing development will shape robotics’ future.

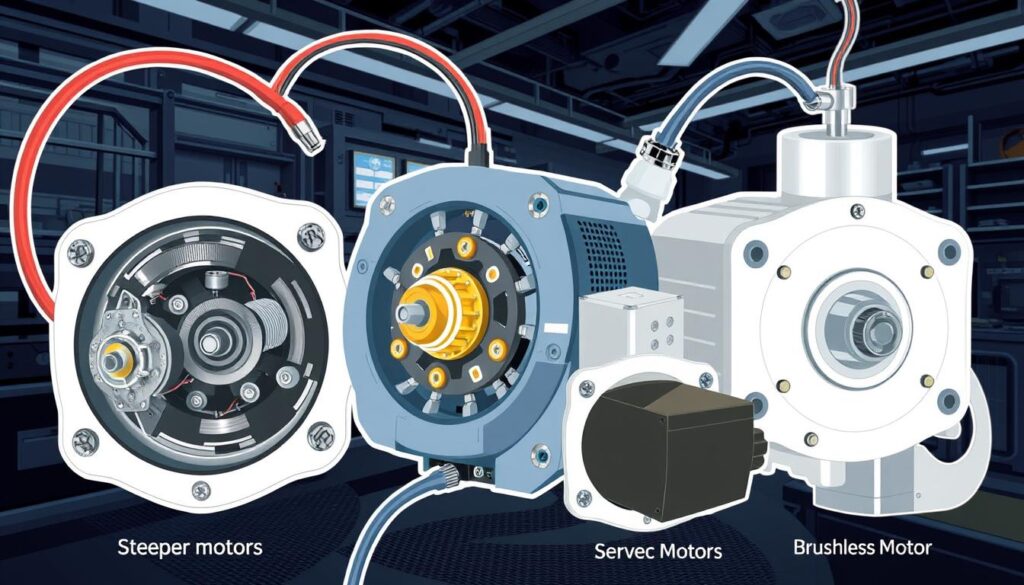

Types of Motors Used in Robotic Arms

Robotic arms use different motors for precise movements. The motor type depends on the task, needed precision, and feedback. We’ll look at the various motors, their benefits, and drawbacks.

Servo motors, stepper motors, DC motors, and linear actuators are common in robotic arms. Each has special features for different tasks. For example, servo motors offer high precision and are great for tasks needing exact positioning.

Servo Motors

Servo motors are popular in robotic arms for their precision and feedback. They come in various sizes and fit many applications, from small arms to big industrial robots.

Stepper Motors

Stepper motors are used for their high torque and slow speed. They’re perfect for tasks needing precise movement. These motors are often chosen for high-precision tasks.

DC Motors

DC motors are common due to their speed and low cost. They’re used in many robotic arms, from small to large. But, they might need extra feedback for precise control.

Linear Actuators

Linear actuators provide linear motion and precise control. They’re ideal for tasks needing high precision, like in manufacturing and assembly lines.

In summary, the motor choice for a robotic arm depends on the task and needed precision. Knowing each motor’s strengths and weaknesses helps designers pick the best one. This ensures the robotic arm moves precisely and accurately.

| Motor Type | Precision Control | Feedback Mechanisms |

|---|---|---|

| Servo Motors | High | Accurate |

| Stepper Motors | High | Precise |

| DC Motors | Low | Additional required |

| Linear Actuators | High | Precise |

Comparing Different Motor Technologies

Robotic arms use different motor technologies, each with its own strengths and weaknesses. The choice depends on the application and needs. Control algorithms are key to the motor’s performance, allowing for precise control.

Position sensing is also vital. It lets the motor know its exact position and orientation. This is needed for precise movements. Some motors, like servo motors, have built-in sensing. Others need external sensors.

Here are some key differences between common motor technologies used in robotic arms:

- Servo motors: known for their high precision and control, but can be more expensive

- Stepper motors: offer high torque and accuracy, but can be noisy and require more power

- DC motors: simple and cost-effective, but may lack precision and control

The right motor technology depends on the application’s needs. This includes speed, torque, and precision. By looking at control algorithms and position sensing, developers can choose the best motor. This leads to more efficient and effective robotic arms.

Precision and Control Systems in Robotic Arm Motors

Precision and control are key in robotic arm motors. They allow the arm to do tasks accurately and reliably. To achieve this, motors use control systems like feedback, algorithms, and position sensing. These systems ensure the motor works as it should, considering load and energy efficiency.

Feedback mechanisms give the motor real-time data on its performance. This is vital when the arm handles heavy loads or does delicate tasks. By using load calculations, the motor can use less energy and avoid damage or failure.

- High-resolution position sensing for accurate movement control

- Advanced control algorithms for real-time adjustments and optimization

- Energy-efficient design to minimize power consumption and reduce heat generation

These features help robotic arm motors achieve high precision and control. They are perfect for many uses, like manufacturing, assembly, medical, and service robotics. As robotic arms become more common, better precision and control systems will be key. They will help these systems do complex tasks accurately and reliably.

| Feature | Description |

|---|---|

| Precision | High-resolution position sensing for accurate movement control |

| Control | Advanced control algorithms for real-time adjustments and optimization |

| Energy Efficiency | Energy-efficient design to minimize power consumption and reduce heat generation |

Motor Selection Criteria for Robotic Arms

Choosing the right motor for a robotic arm is key to its success. Motor selection involves looking at load calculations, energy use, and maintenance needs. These factors are essential for the arm’s performance and efficiency.

A good motor choice can greatly improve a robotic arm’s performance. It allows the arm to move smoothly and accurately. Important things to consider include:

- Load capacity: The motor must handle the arm’s weight and its load.

- Speed and torque: The motor needs enough speed and torque for precise movement.

- Energy efficiency: A more efficient motor saves energy and cuts costs.

- Maintenance requirements: The motor should be easy to maintain and repair.

Engineers must carefully evaluate these factors to find the best motor. This ensures the robotic arm works well and efficiently.

The right motor selection is vital for a robotic arm’s success. It helps the arm perform complex tasks with precision. It also reduces maintenance and operating costs.

Power and Torque Requirements

Understanding power and torque is key for robotic arm motors to work well. To figure this out, we need to calculate the load. This includes the weight and how the arm moves. Keeping things in good shape through maintenance helps a lot.

Calculating the load means looking at the arm’s weight, what it carries, and how it moves. We use this info to find out how much power and torque it needs. It’s important to balance speed and torque, as faster speeds mean less torque. Also, being energy-efficient is key for cost and performance.

- For heavy lifting, you need strong motors.

- Fast assembly needs motors that can move quickly.

- For running all the time, you want motors that use less power.

| Application | Power Requirement | Torque Requirement |

|---|---|---|

| Heavy Lifting | High | High |

| Rapid Assembly | Medium | Low |

| Continuous Operation | Low | Medium |

Knowing about power and torque helps makers design better robotic arms. They can make sure their arms work well for different tasks. Keeping up with maintenance and troubleshooting is vital for avoiding problems and keeping things running smoothly.

Common Applications and Their Motor Requirements

Robotic arm motors are found in many fields like manufacturing, healthcare, and service industries. Each field needs different motors for its tasks. For instance, in manufacturing, robotic arm motors are key for welding, assembly, and moving materials. These tasks need high precision and control.

In healthcare, these motors power surgical robots. These robots must be very precise and accurate for complex surgeries. Motors like servo motors or stepper motors are often used here. They offer the needed precision and control.

Some common uses of robotic arms and their motor needs include:

- Manufacturing: high torque and speed robotic arm motors for tasks such as welding and assembly

- Healthcare: high precision and accuracy robotic arm motors for surgical robots

- Service industries: low to medium torque and speed robotic arm motors for tasks such as material handling and inspection

It’s important to know the motor needs for each use. This helps pick the right motors for the job. By looking at torque, speed, and precision, users can find the best motor for their needs.

Maintenance and Troubleshooting of Robotic Arm Motors

Keeping robotic arm motors in top shape is key. Regular care stops unexpected breakdowns and keeps motors running well. We’ll talk about why maintenance and troubleshooting are so important.

Robotic arm motors need regular checks to work their best. This includes routine inspections to catch problems early. Tasks like oiling parts, checking for wear, and making sure everything is aligned are part of this.

Regular Maintenance Schedule

Having a set maintenance plan helps avoid sudden stops and motor failures. Here are some tasks to include in your schedule:

- Monthly inspections to spot issues early

- Quarterly oiling of moving parts

- Bi-annual wear and tear checks

Common Issues and Solutions

Robotic arm motors can face problems like overheating, shaking, and not working as well. Here are some fixes for these issues:

- Overheating: Make sure there’s good air flow and the motor isn’t too heavy

- Vibration: Check if everything is straight and balanced

- Reduced performance: Look for wear and make sure the motor is well cared for

By sticking to a maintenance plan and fixing common problems fast, robotic arm motors stay in great shape. This means less need for fixing and less time off. Good troubleshooting comes from knowing the motor well and solving problems quickly.

| Maintenance Task | Frequency |

|---|---|

| Inspections | Monthly |

| Lubrication | Quarterly |

| Wear and tear checks | Bi-annually |

Latest Innovations in Robotic Arm Motor Technology

Robotic arm motors have seen big changes in recent years. These changes focus on making them more efficient, precise, and controlled. New motor types, like brushless DC motors and servo motors, are leading the way. They have more torque, speed up faster, and are more accurate.

These new robotic arm motors bring many benefits. They make work more productive, use less energy, and cost less to maintain. For instance, a company using robotic arms for assembly can make better products faster. This means they can work more efficiently and produce higher quality items.

Other advancements include using advanced materials and better control systems. These changes have made the motors smaller, lighter, and more efficient. Now, they can be used in many fields, from making things in factories to helping in medicine.

Some of the new uses for these robotic arm motors include:

- Industrial automation and manufacturing

- Medical robotics and healthcare

- Aerospace and defense

- Automotive and transportation

These are just a few areas where the latest robotic arm motor technology can be used.

Cost Considerations and ROI

When choosing robotic arm motors, cost considerations are key. It’s important to look at the initial cost, ongoing expenses, and long-term benefits. This helps businesses figure out the return on investment (ROI). The price of these motors can change a lot, based on their type, quality, and brand.

Some important things to think about when looking at cost considerations include:

- Initial investment: The cost of buying and setting up the motor.

- Operating costs: The regular costs for keeping the motor running, like energy and repairs.

- Long-term value analysis: The benefits and savings from better efficiency, productivity, and lower labor costs.

By looking at these points, businesses can make smart choices about their motor investments. It’s important to compare the costs to the benefits and think about the overall value.

An in-depth look at cost considerations and ROI helps businesses make the most of their motor investments. The table below shows the main points to consider:

| Factor | Description |

|---|---|

| Initial Investment | Upfront cost of purchasing and installing the robotic arm motor |

| Operating Costs | Ongoing expenses associated with maintaining and running the motor |

| Long-term Value Analysis | Potential benefits and savings achieved through increased efficiency and productivity |

Conclusion

Motors in robotic arms are key to their precise and efficient work. Servo motors, stepper motors, and linear actuators each have a vital role. They provide the power, torque, and control needed for various tasks.

Choosing the right motors is essential for engineers. It ensures the robotic arms work well, use less energy, and last longer. This is important for their projects’ success.

The role of motor technology in robotics is growing. New designs and control systems are making robotic arms more precise and adaptable. Keeping up with these advancements helps professionals use robotic automation to its fullest.