Robot motors are key in robotics, letting robots move and do tasks. The motors a robot has show what it can do. Knowing about robot motors helps us understand robotics better.

Robot motors are important for robots to work with their surroundings. There are many types, like DC motors and servo motors, each for different tasks. The number and type of motors change based on the robot’s job.

Exploring robotics shows us how vital robot motors are. The motors a robot has affect its performance and what it can do. We’ll look into robot motors, their role in robotics, the different types, and how many a robot might need.

Understanding Robot Motors: The Basics

Robot motors are key for robots to do their jobs. In industrial robots, they help with making things. In service robots, they assist with cleaning and helping people. The motor type needed depends on the task, with each type having its own benefits.

There are many types of robot motors, like DC, stepper, and servo motors. Each has its own good points and not-so-good points. For instance, DC motors are great for industrial robots because they’re strong and fast. Stepper motors are better for service robots because they’re precise and controlled.

What Is a Robot Motor?

A robot motor changes electrical energy into movement. Choosing the right motor is very important. It affects how well the robot works.

Different Types of Robot Motors

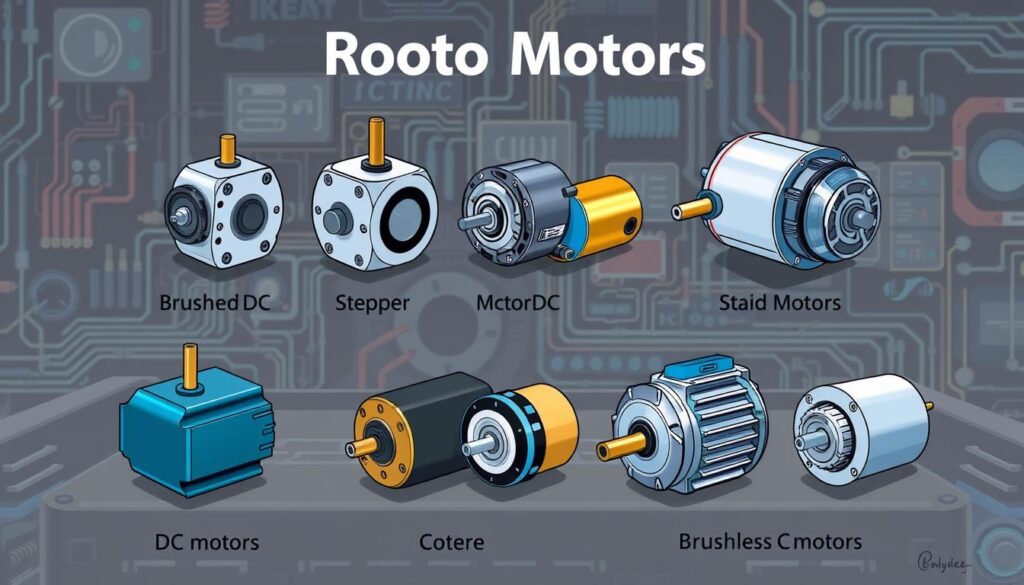

Here are some common robot motors:

- DC motors: known for their high torque and speed

- Stepper motors: offer high precision and control

- Servo motors: provide high accuracy and reliability

The Role of Motors in Robotics

In robotics, motors are very important. They let robots move and do tasks. By picking the right motor, robots can work better and more efficiently. This makes them key for both industrial robots and service robots.

| Motor Type | Characteristics | Applications |

|---|---|---|

| DC motors | High torque and speed | Industrial robots |

| Stepper motors | High precision and control | Service robots |

| Servo motors | High accuracy and reliability | Industrial and service robots |

Common Robot Types and Their Motor Requirements

When it comes to consumer robots, the motor needs change a lot. For example, a robotic vacuum cleaner needs motors for moving and sucking up dirt. On the other hand, a robotic arm for making things needs strong motors for precise movements.

The design and purpose of a robot decide how many and what type of motors it needs. This affects where the motors are placed and how well the robot works.

Here are some common robot types and their motor needs:

- Robotic vacuum cleaners: 2-3 motors for movement and suction

- Robotic arms for manufacturing: 4-6 motors for precise movement and manipulation

- Autonomous robots: 2-4 motors for movement and navigation

For consumer robots, the motor needs are simpler than for industrial robots. But, where and how the motors are placed can greatly affect the robot’s performance. Knowing what motors different robots need helps makers create robots for various tasks, from cleaning homes to making things in factories.

| Robot Type | Motor Requirements | Motor Placement |

|---|---|---|

| Robotic Vacuum Cleaner | 2-3 motors | Bottom and side of the robot |

| Robotic Arm for Manufacturing | 4-6 motors | Along the arm and at the joints |

| Autonomous Robot | 2-4 motors | Wheels and navigation system |

How Many Motors Does a Robot Have? A Comprehensive Analysis

Figuring out how many motors a robot has depends on its type and purpose. Robot motor technology has grown a lot. This means different robots need different motors for their jobs. For example, industrial robots might need many motors for tasks like welding and assembly.

Service robots, like those in healthcare, might have fewer motors. But these motors are very good at what they do. Consumer robots, like vacuum cleaners, can have just one or a few motors. The types of robot motors used affect how well a robot works.

Industrial Robots and Their Motor Count

Industrial robots need lots of motors because they do hard work. They use strong motors for tasks like welding and moving heavy things. The number of motors in an industrial robot can vary a lot, based on what it does.

Service Robots and Motor Requirements

Service robots, like those in healthcare, usually have fewer motors. But these motors are very good at their jobs. The motors in service robots need to be flexible and precise, depending on their task.

Consumer Robots and Their Motors

Consumer robots, like vacuum cleaners, often have just one motor. These motors are made to do one thing well and save energy. The robot motor technology keeps getting better, making consumer robots more efficient.

Factors That Determine Motor Count in Robots

Several factors decide how many motors a robot needs. The robot’s size, complexity, and purpose are key. A bigger, more complex robot might need more motors. On the other hand, a smaller, simpler robot might get by with fewer.

For service robots and consumer robots, where motors are placed matters a lot. Motor placement affects how well a robot works, mainly when space and weight are important. Here are some main factors that influence how many motors a robot needs:

- Robot size and complexity: Larger, more complex robots need more motors to work right.

- Application requirements: Each task, like speed, torque, and precision, affects how many motors are needed.

- Design considerations: A robot’s design, including its mechanical and electrical parts, impacts motor count and motor placement.

Knowing these factors is key to making efficient and effective robots. Whether they’re service robots or consumer robots, manufacturers can choose the right motor count and motor placement. This ensures the robot performs well and efficiently.

Motor Placement and Configuration in Robots

Motor placement and configuration are key to a robot’s performance. The right motor placement boosts a robot’s efficiency and function. New robot motor technology offers more flexible and efficient motor setups. This leads to better robot performance in many areas.

Important things to think about for motor placement and setup include:

- Optimal weight distribution for stability and balance

- Efficient power transmission to cut down energy loss

- Compact design for smaller size and better movement

Robot designers can make robots that do great in their jobs by thinking about these points. The latest robot motor technology helps robots perform well while being small and using less energy.

As robot motor technology keeps getting better, we’ll see even more smart motor setups. These will make robots more efficient and effective in their tasks.

The Impact of Motor Selection on Robot Performance

Choosing the right motor is key for a robot’s performance. Different motors fit different needs. For example, industrial robots need motors that handle heavy loads and precise movements. On the other hand, service robots require motors that are efficient and reliable.

The motor type affects a robot’s speed, torque, and power use. DC motors are good for fast, low-torque tasks. Stepper motors are better for precise, slow tasks. Service robots often use DC motors for their efficiency and reliability.

Motor placement and setup also matter a lot. A well-placed motor can improve a robot’s balance and performance. Here are some key things to think about when picking a motor for a robot:

- Speed and torque needs

- Power use

- Precision and control

| Motor Type | Application | Characteristics |

|---|---|---|

| DC Motor | Industrial Robots | High speed, low torque |

| Stepper Motor | Service Robots | High precision, low speed |

| Servo Motor | Consumer Robots | High precision, high speed |

Modern Trends in Robot Motor Technology

Robot motor technology is advancing fast, making robots more efficient and powerful. This is great for consumer robots that need to be strong yet small and use less energy. Designers are finding new ways to put motors in robots to make them better.

New materials like rare-earth magnets are being used, and control systems are getting smarter. These changes help make motors stronger, more precise, and reliable. For instance, some consumer robots can now move with great accuracy, doing things they couldn’t before.

Brushless motors are becoming popular for their efficiency and dependability. Modular motor systems are also being developed, making it easier to add motors to designs. These advancements will keep pushing the limits of what robots can do. As motor placement gets better, we’ll see even more amazing things from consumer robots and other robots.

Common Challenges in Robot Motor Implementation

Implementing robot motors comes with its own set of challenges, mainly for industrial robots and service robots. One big issue is maintenance. Robot motors wear out and need regular checks to work well.

Cost is another big challenge. The price of types of robot motors can be high, and upkeep costs can pile up. But, choosing the right motor and designing it well can save money in the long run. Here are some common problems with robot motor implementation:

- Maintenance issues: regular servicing and replacement of parts

- Cost considerations: initial cost, maintenance cost, and possible savings

- Performance limitations: balancing speed, torque, and precision

It’s key to know these challenges to overcome them. This ensures robot motors work well in industrial robots and service robots. By picking the right types of robot motors and designing them smartly, makers can cut costs and boost performance.

By tackling these issues, makers can build better robots. These robots will be more efficient and meet the needs of many industries, from making things to healthcare. With the right strategy, industrial robots and service robots can do complex tasks with great precision, changing how we work and live.

| Challenge | Description |

|---|---|

| Maintenance issues | Regular servicing and replacement of parts |

| Cost considerations | Initial cost, maintenance cost, and possible savings |

| Performance limitations | Trade-offs between speed, torque, and precision |

Conclusion: The Future of Robot Motors

The future of robot motors looks very promising. We’ve seen big changes in consumer robots and industrial robots. These changes will keep making robots more efficient and precise.

New technologies like advanced servo motors and brushless DC motors are coming. They will make robots faster and use less energy. We might also see easier ways to change and add parts to robots.

Even though there are challenges like cost and maintenance, the industry is working hard to solve them. Robots will soon change many areas of life, from making things to helping us at home. The future of robot motors is very exciting, and it’s up to us to imagine what’s possible.