In the world of industrial automation, industrial robot motors are key to boosting efficiency and productivity. There are many types of motors to choose from, each suited for different tasks. These motors are vital for precise control and movement in modern manufacturing.

Knowing the different motors used in industrial robots is key to improving automation. By looking into the various options, manufacturers can make better choices. The aim is to find the right mix of performance, reliability, and cost. This is important in today’s fast-paced world, where these motors are always getting better to meet automation needs.

Understanding Industrial Robot Motors: Basic Principles

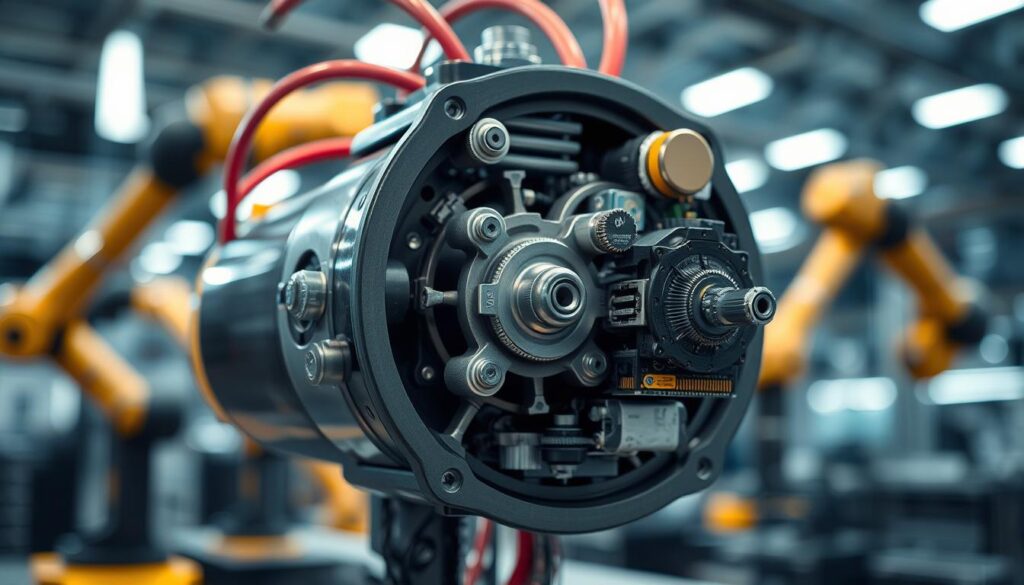

Industrial robot motors are key in industrial robotics. They help robots do tasks with great precision. To get how these motors work, we need to know the robot motor basics. This includes their role, the parts they have, and the power needed for different tasks.

Role of Motors in Industrial Robotics

Motors are very important in industrial robotics. They give the power and movement needed for tasks like assembly and welding. Motors drive the robot’s joints, letting it move and work with its surroundings.

Key Components of Robot Motors

The main parts of robot motors are motor components like gears, bearings, and controllers. These parts work together to give the robot the power and movement it needs. Knowing about these parts is key to picking the right motor for a job.

Power and Torque Requirements

The power and torque needs of industrial robot motors change based on the task. For example, a heavy-duty material handling robot needs a motor with lots of torque and power. But a robot for precise assembly needs a motor with less torque but high precision. It’s important to know what a task needs to pick the right motor and ensure it works well.

| Motor Type | Power Output | Torque Output |

|---|---|---|

| DC Motor | 100W | 10Nm |

| AC Motor | 500W | 50Nm |

| Stepper Motor | 50W | 5Nm |

What Types of Motors Are Used in Industrial Robots: A Comprehensive Overview

Industrial robots use different motors for precise tasks. The right motor depends on the job, like servo, stepper, linear, or hydraulic actuators. Each motor has special features and uses.

Choosing a motor for a robot means looking at power, torque, and speed. Servo motors are great for precise tasks like assembly. Stepper motors are best for tasks needing lots of torque and slow speed, like in robotic arms.

Linear motors are perfect for fast and accurate tasks, like moving materials. Hydraulic actuators handle heavy tasks, like welding, because they offer lots of force and torque.

| Motor Type | Characteristics | Applications |

|---|---|---|

| Servo Motors | High precision, high accuracy | Assembly, inspection, material handling |

| Stepper Motors | High torque, low speed | Robotic arms, grippers, material handling |

| Linear Motors | High speed, high accuracy | Material handling, processing, packaging |

| Hydraulic Actuators | High force, high torque | Heavy-duty material handling, welding, assembly |

In summary, picking the right motor for a robot depends on the task. Knowing what each motor does helps choose the best one. This ensures the robot works well and efficiently.

Servo Motors: The Backbone of Precision Robotics

Servo motor technology is key in precision robotics. It makes high-precision tasks easy. Precision robotics needs servo motors for their precise movement and positioning.

Motor control systems are also vital. They let us control servo motors precisely. This ensures the motors work as they should. Together, servo motors and motor control systems make precision robotics reliable and accurate.

Using servo motors in precision robotics has many benefits. These include:

- High precision and accuracy

- Fast and reliable movement

- Low vibration and noise

- Long lifespan and low maintenance

In summary, servo motor technology is essential for precision robotics. It allows for precise tasks and control. With servo motors and advanced motor control systems, precision robotics can be very accurate and reliable. This makes them perfect for many applications.

| Motor Type | Precision | Speed | Reliability |

|---|---|---|---|

| Servo Motor | High | Fast | High |

| Stepper Motor | Medium | Medium | Medium |

| Linear Motor | High | Fast | High |

Performance Characteristics of Industrial Robot Motors

When looking at industrial robot motors, it’s key to check their performance. This includes how well they work, their speed, and how they control torque. These aspects greatly affect the robot’s efficiency and success in different tasks.

The motor’s speed and how fast it can move are very important. High-speed motors are great for fast tasks like assembly lines or packaging. Motors with lots of torque are better for heavy lifting or precise work, like welding or moving materials.

Key Performance Factors

- Speed and acceleration: affecting the robot’s ability to perform tasks quickly and efficiently

- Torque output and control: influencing the robot’s ability to handle heavy loads or precise movements

- Precision and repeatability: impacting the robot’s ability to consistently perform tasks with high accuracy

Knowing these performance traits is vital for picking the right motor for a job. By looking at motor performance, speed, and torque control, makers can make their robots better. This leads to more productivity, efficiency, and reliability.

By carefully checking these traits, makers can make sure their robots have the best motors. This means the robots will work better and be more productive.

| Motor Type | Speed and Acceleration | Torque Output and Control |

|---|---|---|

| Servo Motors | High speed and acceleration | Precise torque control |

| Stepper Motors | Medium speed and acceleration | High torque output |

| Linear Motors | High speed and acceleration | Low torque output |

Power Sources and Control Systems

When it comes to industrial robot motors, power sources are key. They affect how well the motor works and how efficient it is. Electric power sources are often better than hydraulic or pneumatic ones.

Control systems are also vital for motor performance. They help control the motor’s speed, torque, and position. This makes the motor work smoothly and efficiently. New control systems have made motors more reliable and flexible.

When picking a power source and control system, consider a few things:

- Power density and efficiency

- Control precision and accuracy

- Reliability and durability

- Flexibility and adaptability

Choosing the right power source and control system is important. It helps make industrial robot motors better. This means they work better, last longer, and cost less to run.

Applications Across Different Industries

Industrial automation has changed how many industries work. Robotics in manufacturing boosts efficiency and productivity. Industrial robot motors help in this, making processes smoother across industries.

In car making, these motors handle welding, assembly, and checks. They also help in electronics, like soldering and placing parts. Food processing gets better with them, for packaging and sorting.

The aerospace field also benefits a lot. Motors are used for drilling, cutting, and putting together plane parts. Their flexibility makes them key in many areas, leading to better precision and accuracy.

| Industry | Application |

|---|---|

| Automotive Manufacturing | Welding, Assembly, Inspection |

| Electronics Assembly | Soldering, Component Placement |

| Food Processing | Packaging, Sorting, Inspection |

| Aerospace | Drilling, Cutting, Assembly |

As automation grows, so will robotics in manufacturing. This will lead to more uses across industries. Industrial robot motors will keep improving efficiency, productivity, and accuracy, shaping the future of many fields.

Maintenance and Longevity Considerations

Keeping industrial robot motors in good shape is key to their long life. Regular care helps avoid downtime and boosts system performance. A set maintenance schedule can make motors last longer and cut down on unexpected failures.

Important motor maintenance steps include preventive care like lubrication, cleaning, and checking motor parts. This helps spot problems early. Also, watching common wear points like bearings and gears can stop them from wearing out too soon.

Preventive Maintenance Schedules

- Regularly inspect and clean motor components

- Lubricate moving parts to reduce friction and wear

- Monitor motor performance and adjust as needed

Following a preventive maintenance plan helps keep motors running well for longer. It also saves money on repairs. Good motor care is vital for system performance and less downtime.

Troubleshooting Guidelines

Having a plan for fixing motor failures is critical. It helps find the problem fast and cuts downtime. A structured troubleshooting approach ensures motors last longer and systems run smoothly.

Environmental Factors and Motor Selection

Choosing the right motor for industrial robots is key. The environment they work in matters a lot. Things like temperature, humidity, and dirt can affect how well a motor works and how long it lasts.

In factories, motors face tough conditions. High heat can make them overheat. Too much moisture can cause rust and harm. Dust, dirt, and chemicals can also hurt their performance and shorten their life. Knowing these environmental challenges helps pick the right motor for the job.

- Temperature range: Can the motor work well in very hot or cold temperatures?

- Humidity levels: Is the motor made to handle lots of moisture?

- Contaminant exposure: Can the motor stand up to dust, dirt, or chemicals?

By looking at these environmental factors and choosing motors that can handle them, manufacturers can make their robots work better, last longer, and be more reliable.

| Environmental Factor | Impact on Motor Performance | Recommended Motor Features |

|---|---|---|

| High Temperature | Overheating, reduced lifespan | Heat-resistant materials, cooling systems |

| High Humidity | Corrosion, damage | Water-resistant coatings, sealed enclosures |

| Contaminant Exposure | Damage, reduced efficiency | Sealed enclosures, air filters, corrosion-resistant materials |

Latest Innovations in Robot Motor Technology

The world of industrial robotics is always changing. Robot motor innovations are key in shaping the future of making things. Smart motors will lead this change, making production more efficient and flexible.

Companies are focusing on energy efficiency to cut costs and reduce harm to the environment. New robot motor innovations have made more efficient motors. These motors use advanced materials and designs to save energy and reduce heat.

- Advanced control systems that enable real-time monitoring and optimization of motor performance

- Integrated sensors and feedback mechanisms that allow for more precise control and adjustment

- New materials and designs that improve efficiency and reduce energy consumption

As the industry grows, we’ll see even more new ideas. These will improve energy efficiency and performance. With smart motors and other advanced tech, the future of industrial robotics is exciting. Manufacturers will gain a lot from these robot motor innovations.

Conclusion: Choosing the Right Motor for Your Industrial Robot

The world of industrial robot motors is vast and diverse. There are many options to consider for your specific application. When picking the perfect motor, it’s key to look at motor selection, industrial robot motor needs, and application-specific requirements.

Understanding motor performance, power sources, and control systems is vital. This ensures your robot works efficiently, precisely, and reliably. Whether you need speed, torque, or versatility, choose a motor that fits your application’s needs.

Keep up with the latest in robot motor tech, like smart motors and advanced controls. These can boost your robot’s performance, energy use, and lifespan.

The right motor selection for your industrial robot motors is critical for success. Follow the advice in this article to pick the best motor for your needs. This will help your industrial robot reach its full capability.